Product

Silver Alloy Metallized Wire

Product Description

It’s nickel chromium ultra-high strength conductive/heating wire. its’ more flexibility and long working life than other wires, as the aramid / carbon yarn inside can bears the vertical tensile strength.

Advantages

1.Heat-resistant, special for heating

2.High tensile strength,

3. Bending resistance. Not easy to break

4. Good corrosion resistance and high reliability

5. Low resistance and conductivity

Materials Available

Nickel chromium, copper, tin-plated, silver-plated, gold-plated,nickel-plated,bare copper alloy, tin copper alloy , silver copper alloy etc. All wire can be designed and customized according to customers’ request of performance, technical Parameters, outer diameter etc.

Outer diameter range: 0.05mm-0.40mm.

Extruion(insulation coating) available,material can be PVC.Teflon etc according to your specify.

Stranding available.

Regualer specification

|

Outer Conductor |

Textile Inner Core |

Diameter mm |

Conductivity ≤Ω/m |

Weight m/KG |

Elongation≥% |

Strength ≥KG |

|

Copper 0.08mm |

250D Poyester |

0.20±0.02 |

6.50 |

9000±150 |

8 |

1.50 |

|

Copper 0.10mm |

250D Polyester |

0.23±0.02 |

3.90 |

7000±200 |

10 |

1.50 |

|

Copper 0.05mm |

50D Kuraray |

0.10±0.02 |

12.30 |

28000±1500 |

3 |

0.70 |

|

Copper 0.1mm |

200D Dinima |

0.22±0.02 |

4.00 |

7000±200 |

5 |

4.00 |

|

Copper 0.1mm |

250D Polyester |

1*2/0.28 |

2.00 |

5300±500 |

8 |

1.50 |

|

Copper 0.1mm |

200D Kevlar |

0.22±0.02 |

4.00 |

7300±200 |

5 |

3.80 |

|

Copper 0.05mm |

50D Polyester |

1*2/0.13 |

8.50 |

28000±1500 |

5 |

0.35 |

|

Copper 0.05mm |

70D Polyester |

0.11±0.02 |

12.50 |

21500±1500 |

5 |

0.45 |

|

Copper 0.55mm |

70D Polyester |

0.12±0.02 |

12.30 |

21000±1500 |

5 |

0.45 |

|

Copper 0.10mm |

Cotton 42S/2 |

0.27±0.03 |

4.20 |

6300±200 |

7 |

1.10 |

|

Copper 0.09mm |

150D Polyester |

0.19±0.02 |

5.50 |

9500±200 |

7 |

0.90 |

|

Copper 0.06mm |

150D Polyester |

0.19±0.02 |

12.50 |

16500±500 |

7 |

0.90 |

|

Tin Copper 0.085mm |

100D Kuraray |

0.17±0.02 |

5.00 |

16000±1000 |

5 |

2.00 |

|

Tin Copper 0.08mm |

130D Kevlar |

0.17±0.02 |

6.60 |

14500±100 |

5 |

2.00 |

|

Tin Copper 0.06mm |

130D Kevlar |

0.16±0.02 |

12.50 |

21000±500 |

3 |

2.00 |

|

Tin Copper 0.10mm |

250D Polyester |

0.23±0.02 |

4.00 |

7000±200 |

8 |

1.50 |

|

Tin Copper 0.06mm |

150D Polyester |

0.16±0.02 |

11.6 |

14000±1000 |

7 |

0.90 |

|

Tin Copper 0.085mm |

200D Kevlar |

0.19±0.02 |

5.00 |

8500±300 |

5 |

3.80 |

|

Tin Copper 0.085mm |

150D Polyester |

0.19±0.02 |

6.00 |

9500±200 |

7 |

0.90 |

|

Silver Copper 0.10mm |

250D Polyester |

0.23±0.02 |

3.90 |

7000±200 |

8 |

1.5 |

Winding direction: “Z”is bunched in a clockwise direction, “S” is the opposite direction.

Applications

Mainly used in automobile seat heating, intelligent clothing heating, electric heating elements used in electric furnace, household electric appliances, far infrared device, cartridge heaters.

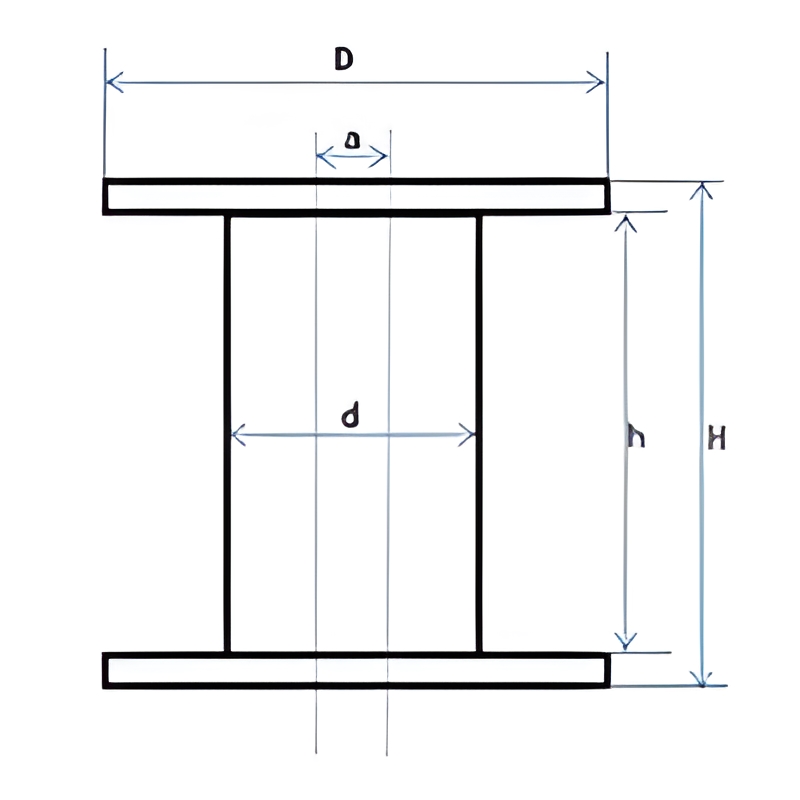

Spool Size

P.S: Special spool can made according to customers’ requested model and size.