Product

Stainless steel bundle fiber or textile inner core conductive wire for heatable textiles

Product Description

1-Stainless steel fiber based bundle where the diameter of each individual fiber is 12µ or 14µ. The amount of fibers ranges typically from around 200 to over 1500 filaments. This gives you a durability which is by far ‘best in class’. Because of the fine fibers used, these cables still remain thin in overall diameter and thus very flexible in processing.

2-We covers a wider range of lower resistance extra fine wire and micro cables with durable and flexiable characties,special our with textile inner core micro cables can statisfy the resistance per meter you needs and gives you more flexibility in design but still offers a better flex-life than typical Cu-cables. Depending on outer wrapped alloy which can be tinned,copper,silver alloy etc, we can produce conductive resistant even lower than 1 ohm/m micro cables by single and stranded types according to customer requirement.

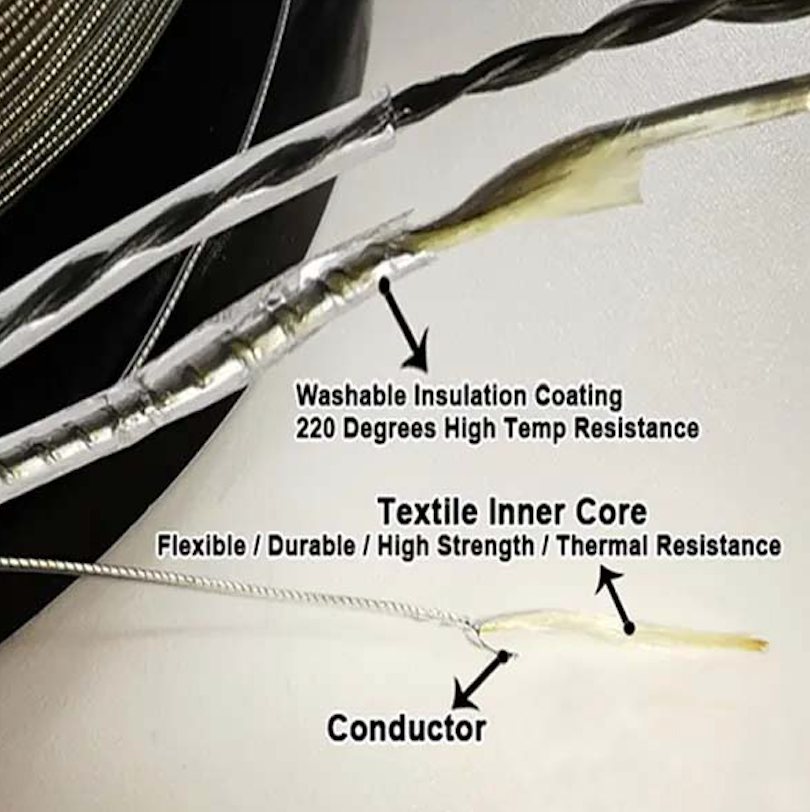

Textile inner core micro cables advantages

Bending Resistance

Because of the structure and combination of materials, the wire has excellent bending resistance.

Flexibility

The micro cables uses very thin metal foil as conductor, that realizes super flexibility.

Ultra-Fine

After extrusion our micro cable thinest can be to 0.35mm.

High Tensile Strength

We use Aramid / Liquid Crystal Polymer fibers and self engineer high tech fibers.

High Temp. Resistance

We use aramid or stanless steel fiber bundle filaments for fibers,high temp resistant from 230 degrees to 580 degrees for your choice.

Finishing & coating

In your world, there is mostly need for individual lacquering of the filaments or an overall extrusion coating over the complete cable. We can also do that,our extrusion contents include FEP,PFA,PTFE,TPU etc.

INSULATION JACKET DESCRIPTION

| Extrusion | TPE | FEP | MFA |

| Melting Point | 205° C | 255° C | 250° C |

| Continuous Working Temperature | 165° C | 205° C | 225° C |

Stainless Steel Fiber Bundles

Textile Inner Core Micro Cable Constructions

Based Embroided Heating Element

Stainless steel bundels different resistance ranges for your reference.

|

Diameters (um) |

Filaments |

Strength (cN) |

Weight (g/m) |

Elongation (%) |

Conductivity (Ohm/ m) |

|

8 |

1000F x 1 |

69 |

0.420 |

1.10 |

16 |

|

8 |

1000F x 2 |

108 |

0.850 |

1.10 |

8 |

|

12 |

100F x 1 |

24 |

0.110 |

1.10 |

59 |

|

12 |

100F x 2 |

41 |

0.190 |

1.10 |

38 |

|

12 |

100F x 3 |

69 |

0.280 |

1.10 |

22 |

|

12 |

257F x 1 |

59 |

0.260 |

1.10 |

27 |

|

12 |

275F x 2 |

75 |

0.540 |

1.10 |

14 |

|

12 |

275F x 3 |

125 |

0.780 |

1.10 |

9 |

|

12 |

275F x 4 |

130 |

1.050 |

1.10 |

7 |

|

12 |

275F x 5 |

160 |

1.300 |

1.10 |

5 |

|

12 |

275F x 6 |

180 |

1.500 |

1.10 |

4 |

|

12 |

1000F x 1 |

100 |

0.950 |

1.10 |

7 |

|

12 |

1000F x 2 |

340 |

1.900 |

1.10 |

4 |

|

14 |

90F x 2 |

46 |

0.190 |

1.10 |

44 |

|

14 |

90F x 1 |

25 |

0.110 |

1.10 |

Textile inner core conductive wire different resistance ranges

|

Outer Conductor |

Textile Inner Core |

Diameter mm |

Conductivity ≤Ω/m |

|

Copper 0.08mm |

250D Poyester |

0.20±0.02 |

6.50 |

|

Copper 0.10mm |

250D Polyester |

0.23±0.02 |

3.90 |

|

Copper 0.05mm |

50D Kuraray |

0.10±0.02 |

12.30 |

|

Copper 0.1mm |

200D Dinima |

0.22±0.02 |

4.00 |

|

Copper 0.1mm |

250D Polyester |

1*2/0.28 |

2.00 |

|

Copper 0.1mm |

200D Kevlar |

0.22±0.02 |

4.00 |

|

Copper 0.05mm |

50D Polyester |

1*2/0.13 |

8.50 |

|

Copper 0.05mm |

70D Polyester |

0.11±0.02 |

12.50 |

|

Copper 0.55mm |

70D Polyester |

0.12±0.02 |

12.30 |

|

Copper 0.10mm |

Cotton 42S/2 |

0.27±0.03 |

4.20 |

|

Copper 0.09mm |

150D Polyester |

0.19±0.02 |

5.50 |

|

Copper 0.06mm |

150D Polyester |

0.19±0.02 |

12.50 |

|

Tin Copper 0.085mm |

100D Kuraray |

0.17±0.02 |

5.00 |

|

Tin Copper 0.08mm |

130D Kevlar |

0.17±0.02 |

6.60 |

|

Tin Copper 0.06mm |

130D Kevlar |

0.16±0.02 |

12.50 |

|

Tin Copper 0.10mm |

250D Polyester |

0.23±0.02 |

4.00 |

|

Tin Copper 0.06mm |

150D Polyester |

0.16±0.02 |

11.6 |

|

Tin Copper 0.085mm |

200D Kevlar |

0.19±0.02 |

5.00 |

|

Tin Copper 0.085mm |

150D Polyester |

0.19±0.02 |

6.00 |

|

Silver Copper 0.10mm |

250D Polyester |

0.23±0.02 |

3.90 |