Product

Polyester With Cables Elastic Strap

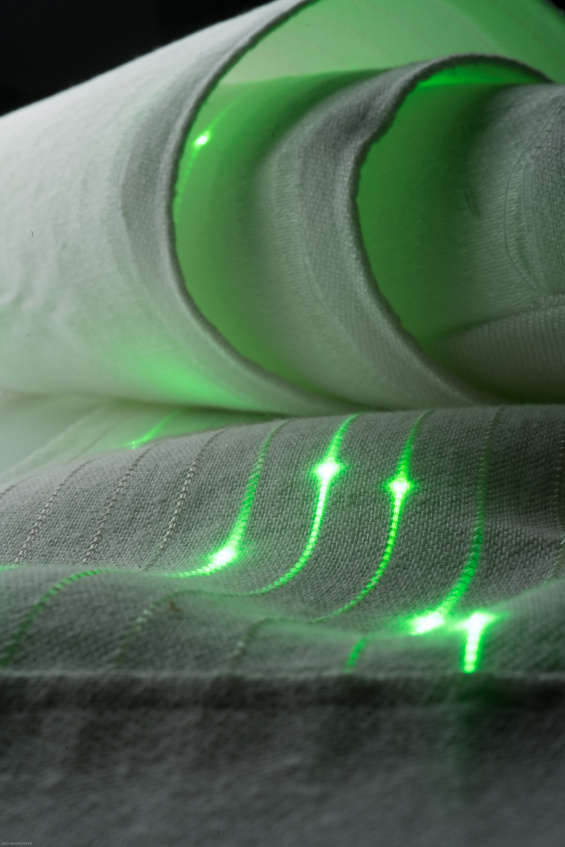

E-TEXTILE NARROW FABRICS USING MICRO CABLES OR CONDUCTIVE YARNS

We Specialty Narrow Fabrics has the technical expertise to integrate wires, monofilaments, and conductive yarns into narrow fabrics for use in numerous textiles applications that can replace or enhance, prior electric/electronic systems. Our ability to engineer products to our customers’ unique configurations will transform traditional fabrics into highly functional integrated systems and products. Your unique textile is now a “device” with the capability to see, hear, sense, communicate, store, monitor, and convert energy and/or data.

OUR E-TEXTILE NARROW FABRICS ARE ENGINEERED IN MULTIPLE CONFIGURATIONS

1. Clients can customize to their own specifications

2. Technical R&D team available for consultative services

3. Various conductive wire or micro cable available to build your e-textile

4. Finishes or insulation coatings are available

EXAMPLES OF SMART FABRIC AND E-TEXTILE END USE APPLICATIONS

● Component of a sports performance monitoring system

● Integrated into a specialized garment to monitor the physiological condition

● Regulate/sense temperature

● Heath monitoring apparel

● Internet-connected apparel – Gaming

● Power and data transmission within military apparel/equipment

● Remote clinical observation devices

● Power source for disaster relief housing

● Underground stress detection

● Heatable textiles

● EMI or RFID shielding

ADVANTAGE OF E-TEXTILE NARROW FABRICS

● Flexible and durable,due to conductive fiber or conductive wire textiles properties so E-TEXTILE NARROW FABRICS more flexible and durable compared to traditional Cu or other metal materials singnal transimission.

● Urtra tiny transmission cable can be used in webbing to save your device space.

● Stable signal transmission

● After conductive wire extrusion E-tapes are washable that can satify any requirement of your used in wading environments.

● High temp resistant and flame retardant requirement avaible,we use aramid yarn to fit with high temp resisntant conductive fibers in that E-TEXTILE NARROW FABRIC even can withstand over 700 degrees high temperture resistant,meanwhile finished E-TEXTIL tapes with TPE,FEP or MFA those high temp resistant material extrusion could make your tape has highly sepcical characters to satify your use webbing under in any severe environments

Extrusion Jacket description

|

Extrusion: |

TPE |

FEP |

MFA |

|

Melting point: |

205° C |

255° C |

250° C |

|

Continuous working temperature: |

165° C |

205° C |

225° C |