Discover the Future of Wearable Technology with Conductive Yarn Innovations

Table of Contents

- Exploring the Basics of Conductive Yarn in Wearable Tech

- Key Innovations Driving the Future of Conductive Yarn

- Applications of Conductive Yarn in Smart Clothing

- Challenges and Solutions in Conductive Yarn Development

- The Impact of Conductive Yarn on Health Monitoring Devices

- Sustainability in Conductive Yarn: A Greener Future for Wearables

- FAQS

- Conclusion

- Related Posts

The wearable technology industry is experiencing a remarkable transformation, driven by innovations in materials like Conductive Yarn. According to a recent report from Grand View Research, the global wearable technology market is expected to reach USD 620 billion by 2025, with smart textiles playing a crucial role in this growth.

At the forefront of this revolution is Shijiazhuang Shielday Technology Co., Ltd., a leading manufacturer specializing in high-performance EMI shielding textiles and conductive wires. With a robust portfolio of specialty EMI shielding and smart textiles, Shielday Technology Co., Ltd. is poised to capitalize on the rising demand for versatile and adaptable wearable solutions.

As the integration of Conductive Yarn continues to enhance the functionality and comfort of wearable devices, companies like Shielday represent the future of smart textile innovation, providing comprehensive custom product development services that align with market trends and consumer needs.

Exploring the Basics of Conductive Yarn in Wearable Tech

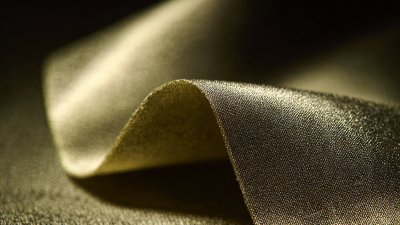

Conductive yarn is revolutionizing the wearable technology industry by integrating electrical functionalities into textiles. At its core, conductive yarn is made from a blend of traditional fibers and conductive materials such as metals or conductive polymers, allowing garments to transmit electrical signals or data. This innovation opens up new possibilities for smart clothing, enabling features such as heart rate monitoring, temperature regulation, and even interactive interfaces directly woven into the fabric.

As the demand for more interactive and functional wearables grows, understanding the basics of conductive yarn becomes essential. These yarns can be woven or knitted into various fabric structures, maintaining the aesthetic and comfort of traditional clothing while providing the additional layer of connectivity. Research and development in this field are focused on enhancing conductivity, durability, and washability, which are critical factors for consumer acceptance. By exploring the mechanics behind conductive yarn and its applications, it becomes clear that these innovations are paving the way for a new era of personal technology seamlessly integrated into everyday life.

Future of Wearable Technology: Conductive Yarn Innovations

Key Innovations Driving the Future of Conductive Yarn

The future of wearable technology is being significantly shaped by the innovations in conductive yarn, which amalgamate textiles with electronics. As reported by ResearchAndMarkets, the global market for conductive yarn is projected to reach $740 million by 2026, growing at a CAGR of 25.4% from 2021. This remarkable growth underscores the increasing demand for smart textiles, driven by advancements in textile engineering and a surge in health and fitness monitoring solutions.

One significant innovation is the integration of nanotechnology into conductive yarn, enhancing both conductivity and durability. For instance, the use of graphene-based conductive fibers has shown to improve performance while maintaining comfort and flexibility, making them suitable for various applications, from athletic wear to medical textiles. Additionally, the advent of IoT connectivity in garments is revolutionizing how users interact with their wearable devices, providing seamless data transfer and enabling real-time health monitoring, as highlighted by a report from Allied Market Research, which states that the smart clothing segment alone could generate revenues exceeding $2 billion by 2023. These developments are setting the stage for a new era of intelligent wearables that are both functional and stylish.

Applications of Conductive Yarn in Smart Clothing

The integration of conductive yarn into smart clothing is revolutionizing the wearable technology landscape, creating opportunities for innovative applications. Conductive yarn acts as a bridge between technology and everyday wear, enabling garments to monitor health metrics, enhance communication, and improve user interactivity. This advanced approach allows fabrics to not only serve aesthetic purposes but also perform functions traditionally reserved for electronic devices.

At Shijiazhuang Shielday Technology Co., Ltd., our expertise in manufacturing high-performance EMI shielding textiles and conductive wires positions us at the forefront of this evolving industry. We specialize in producing specialty smart textiles that incorporate conductive yarn, allowing fashion designers and technology developers to create garments that respond to user needs. Through our comprehensive custom product development services, we collaborate with clients to transform their innovative ideas into functional, wearable solutions that elevate the future of technology in clothing.

Challenges and Solutions in Conductive Yarn Development

The development of conductive yarn for wearable technology is paving the way for a revolution in smart textiles. However, this journey is not without its challenges. One of the primary obstacles faced by manufacturers, such as Shijiazhuang Shielday Technology Co., Ltd., is ensuring consistency in conductivity while maintaining fabric flexibility and comfort. Balancing these factors is crucial, as the success of wearable technology hinges on user experience as well as performance.

Another significant challenge lies in the integration of conductive yarn into various textile applications. This requires a collaborative approach, involving ongoing research and development to refine production methods. Shielday Technology is committed to addressing these challenges by leveraging its expertise in high-performance EMI shielding textiles and conductive wires. Through careful design and robust testing, innovative solutions can be developed that will meet the evolving demands of the wearable technology market.

**Tip:** When exploring conductive yarn applications, consider not only the technical specifications but also the end-user's experience. Ensuring that the final product is both functional and comfortable is key to its adoption in the mainstream market. Additionally, collaborating with experts in smart textiles can help overcome potential integration hurdles.

The Impact of Conductive Yarn on Health Monitoring Devices

The advent of conductive yarn technology is revolutionizing health monitoring devices, bringing newfound flexibility and accuracy to the field. Conductive yarn, which is woven with conductive materials, allows garments to seamlessly integrate electronic components while maintaining comfort and wearability. This innovation empowers users to track vital signs, such as heart rate and temperature, without the bulkiness of traditional devices. As these materials become more common in everyday clothing, the opportunity for

continuous health monitoring becomes increasingly viable, merging fashion with function.

Moreover, the impact of conductive yarn on health monitoring extends beyond just tracking. It opens avenues for real-time data analysis and alerts, helping users manage chronic conditions effectively. For instance, individuals with heart conditions can receive immediate feedback about their heart rate fluctuations, which can be crucial for timely medical responses. As this technology continues to evolve, the integration of conductive yarn in textiles promises an enhanced capability for personalized healthcare, allowing individuals to take a

proactive approach to their well-being.

Sustainability in Conductive Yarn: A Greener Future for Wearables

As the demand for sustainable fashion grows, innovative advancements in conductive yarn technology are paving the way for a greener future in wearable electronics. Conductive yarn, made from eco-friendly materials, not only enhances the functionality of textiles but also minimizes environmental impact. This innovative approach is transforming how we perceive smart textiles, moving beyond mere functionality to embrace sustainability. As consumers become more environmentally conscious, brands are increasingly focusing on integrating sustainable practices in yarn production, thereby reducing waste and carbon footprints.

Furthermore, the introduction of energy-harvesting textiles, such as denim powered by solar threads, exemplifies how wearable technology can coexist harmoniously with sustainability. These advancements enable everyday apparel to not only serve as a fashion statement but also as a source of energy for devices, promoting a circular economy in fashion. In this landscape of continual improvements, the symbiosis of sustainability and technology is set to define the future of wearable textiles, ensuring that fashion remains not only stylish but also environmentally responsible.

Discover the Future of Wearable Technology with Conductive Yarn Innovations - Sustainability in Conductive Yarn: A Greener Future for Wearables

| Feature | Conductive Yarn Type | Sustainability Rating | Applications | Key Benefits |

|---|---|---|---|---|

| Conductivity | Silver-Plated Nylon | High | Smart Textiles, Health Monitoring | Excellent conductivity, durability |

| Flexibility | Carbon Fiber Yarn | Medium | Wearable Devices, E-Textiles | Lightweight and stretchable |

| Breathability | Conductive Cotton | High | Athletic Wear, Medical Apparel | Comfortable for long-term wear |

| Environmental Impact | Recycled Conductive Yarn | Very High | Sustainable Fashion, Eco-friendly Wearables | Reduces waste and resource consumption |

FAQS

: Conductive yarn is a type of yarn that combines traditional fibers with conductive materials, such as metals or conductive polymers, enabling garments to transmit electrical signals or data.

Conductive yarn allows for the integration of electrical functionalities into textiles, enabling features like heart rate monitoring, temperature regulation, and interactive interfaces directly in the fabric.

The use of conductive yarn provides the advantages of maintaining the aesthetic and comfort of traditional clothing while adding connectivity and functionality to the garments.

Manufacturers must ensure consistency in conductivity while maintaining fabric flexibility and comfort, as balancing these factors is crucial for user experience and performance.

Ongoing research and development are critical for refining production methods and enhancing the performance of conductive yarn to meet the evolving demands of the wearable technology market.

Collaborative approaches involving experts in smart textiles are essential for overcoming integration challenges and ensuring that the final product is both functional and comfortable for users.

Consumers should consider both the technical specifications of conductive yarn and the overall user experience, ensuring that the final product is practical, comfortable, and suitable for everyday use.

Shielday Technology leverages its expertise in high-performance EMI shielding textiles and conductive wires to address challenges through careful design, robust testing, and innovative solutions.

Conductive yarn is paving the way for a new era of personal technology that is seamlessly integrated into everyday life, enhancing the capabilities of wearable devices.

Washability is critical because it ensures that conductive yarn can withstand regular cleaning without losing its conductive properties, making it more appealing to consumers.

Conclusion

Conductive Yarn is rapidly transforming the landscape of wearable technology, offering innovative solutions in smart clothing and health monitoring devices. By exploring the basics, we can understand how this unique material integrates with textiles to create responsive and interactive garments. Key innovations in conductive yarn are driving the future of wearable tech, enhancing functionality while addressing challenges such as durability and performance.

Moreover, the application of Conductive Yarn in health monitoring devices is revolutionizing personal health management, allowing for real-time data collection and analysis. As industries focus on sustainability, the development of eco-friendly conductive yarn presents a greener future for wearable technology, aligning with global initiatives for sustainable practices. Companies like Shijiazhuang Shielday Technology Co., Ltd. are at the forefront, specializing in high-performance textiles that incorporate conductive yarn, thus supporting the evolution of smart textiles through advanced manufacturing and custom product development.

Related Posts

-

Ultimate Guide to Sourcing the Best Nonwoven Fabrics for Restaurant Cleaning Needs

-

Exploring the Market Potential of Stainless Steel Fiber Ribbon at the 138th Canton Fair 2025

-

How to Choose the Right Antibacterial Sock for Ultimate Comfort and Protection

-

Exploring Innovative Applications of Yarn Spuns Pbo Fiber in Modern Textiles

-

Mastering Ef Nonwoven Fabric Techniques for Innovative Applications

-

Ultimate Checklist for Sourcing the Best Silver Conductive Fabric Worldwide