How to Enhance Your Textile Products with Metal Fiber Yarn

Table of Contents

- Benefits of Metal Fiber Yarn in Textile Manufacturing

- Enhancing Durability: The Strength of Metal Fiber Yarn

- Improving Conductivity: Electrical Properties of Metal Fiber in Textiles

- Temperature Regulation: How Metal Fibers Contribute to Thermal Management

- Eco-Friendly Solutions: The Sustainability of Metal Fiber Yarn in Textiles

- Versatile Applications: Using Metal Fiber Yarn in Different Textile Products

- FAQS

- Conclusion

- Related Posts

The textile industry is undergoing a significant transformation, driven by the demand for innovative materials that enhance functionality and performance. One such advancement is the use of Metal Fiber Yarn, which offers unique properties such as improved electromagnetic interference (EMI) shielding, increased durability, and enhanced conductivity. According to a recent industry report by Market Research Future, the global conductive textile market is projected to reach USD 4.41 billion by 2027, growing at a CAGR of 25.4%. As a leader in the manufacturing of high-performance EMI shielding textiles, Shijiazhuang Shielday Technology Co., Ltd. is at the forefront of this revolution, providing specialty solutions that integrate Metal Fiber Yarn into various applications. This guide will explore how to effectively enhance your textile products with Metal Fiber Yarn, demonstrating its potential to meet the evolving needs of industries ranging from automotive to aerospace and beyond.

Benefits of Metal Fiber Yarn in Textile Manufacturing

Metal fiber yarn is revolutionizing the textile manufacturing industry by providing unique benefits that enhance the performance of various products. As an advanced manufacturer, Shielday Technology Co., Ltd. recognizes the growing importance of incorporating metal fiber yarn in the creation of high-performance EMI shielding textiles and conductive wires. The integration of metal fibers not only improves conductivity but also enhances durability, offering textiles that withstand harsh environments.

To effectively incorporate metal fiber yarn into your textile products, consider the following tips. First, evaluate the specific performance requirements of your end product. Whether it’s for EMI shielding or smart textiles, understanding these needs will help determine the ideal fiber composition. Second, explore custom product development services, like those offered by Shielday Technology, to tailor solutions that meet your unique specifications and ensure optimal performance. Lastly, experiment with different blends of metal fiber yarns to achieve the desired balance between flexibility and strength, ultimately enhancing the usability of your textile products.

Enhancing Durability: The Strength of Metal Fiber Yarn

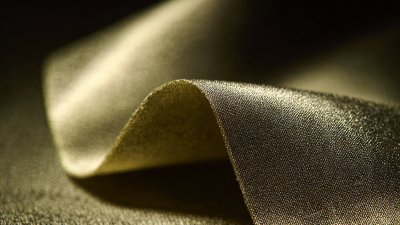

Metal fiber yarn is revolutionizing the textile industry by enhancing the durability of products, making them more resilient in various applications. This innovative material offers superior strength and resistance to wear and tear, ensuring that textiles maintain their functionality and aesthetic appeal over time. The integration of metal fibers in yarns not only improves mechanical properties but also contributes to functionalities such as conductivity, making these yarns ideal for the growing field of wearable electronics.

Recent developments in yarn-based electronics highlight the increasing importance of material performance and surface treatments. As textiles evolve to incorporate more advanced technologies, the focus on enhancing durability through metal fiber yarn becomes paramount. In addition to its mechanical benefits, metal fiber yarn can withstand extreme conditions, including high temperatures and corrosive environments, which opens up new possibilities for multifunctional applications. This synergy between durability and innovation is setting the stage for the next generation of textile products, bridging the gap between traditional fabrics and cutting-edge technology.

Enhancing Durability of Textile Products with Metal Fiber Yarn

Improving Conductivity: Electrical Properties of Metal Fiber in Textiles

In today's rapidly evolving textile industry, incorporating metal fiber yarn into textile products significantly enhances their electrical properties.

Metal fibers, known for their excellent conductivity, can transform standard textiles into high-performance materials suitable for various applications, including EMI shielding and smart textiles. By introducing metal fiber yarn, manufacturers can create fabrics that not only provide durability but also perform impressively in terms of electrical conductivity, making them ideal for devices that require protection from electromagnetic interference.

At Shielday Technology Co., Ltd., we specialize in developing advanced EMI shielding textiles and conductive wires, leveraging our expertise to offer a wide array of specialty products. Our commitment to quality and innovation enables us to provide custom solutions tailored to our clients' unique needs. By integrating metal fiber yarn into your textile products, you can significantly improve their functionality and marketability, opening up new opportunities in sectors ranging from electronics to healthcare.

Temperature Regulation: How Metal Fibers Contribute to Thermal Management

In the realm of textile innovation, metal fibers have emerged as a pivotal component for enhancing temperature regulation in smart textiles. According to a report by Research and Markets, the global smart textile market is anticipated to reach $6.3 billion by 2024, driven predominantly by advancements in thermal management technologies. Metal fibers, which provide exceptional conductivity and durability, allow fabrics to actively respond to environmental temperature changes. This capability is crucial for industries ranging from sportswear to healthcare, where maintaining optimal body temperature can significantly impact performance and comfort.

Shijiazhuang Shielday Technology Co., Ltd. is at the forefront of this innovation, offering a diverse range of high-performance EMI shielding textiles and conductive wires. Our proprietary metal fiber yarns are designed to enhance thermal management by effectively dissipating heat while providing superior EMI protection. Recent studies indicate that textiles incorporating metal fibers can improve thermal regulation by up to 40% compared to traditional fabrics. As the demand for responsive textile solutions continues to grow, investing in metal fiber technology positions manufacturers to meet the evolving needs of consumers seeking high-performance, temperature-regulating apparel.

Eco-Friendly Solutions: The Sustainability of Metal Fiber Yarn in Textiles

Metal fiber yarn is emerging as a remarkable eco-friendly solution for enhancing textile products. As consumers become more conscious of sustainability, the demand for innovative materials that reduce environmental impact is on the rise. Metal fiber yarn, made from recycled metals, provides a unique approach to textile production by offering durability and conductivity without compromising the planet. This sustainable option allows manufacturers to create high-performance fabrics that do not rely on traditional, resource-intensive materials.

The incorporation of metal fiber yarn in textiles also presents an opportunity for various applications, from fashion to technical textiles. This innovative material can improve the functionality of garments, making them more versatile and long-lasting. Additionally, the ability to recycle metal fibers at the end of a product's lifecycle further emphasizes the sustainability aspect, reducing waste and promoting a circular economy. By adopting metal fiber yarn, brands can not only meet the growing consumer demand for eco-friendly options but also contribute positively to environmental conservation initiatives.

How to Enhance Your Textile Products with Metal Fiber Yarn - Eco-Friendly Solutions: The Sustainability of Metal Fiber Yarn in Textiles

| Aspect | Details |

|---|---|

| Material Composition | Metal Fiber Yarn is typically made from stainless steel or other recyclable metals. |

| Sustainability | Metal Fiber Yarn is durable, extending the lifecycle of textile products and reducing waste. |

| Applications | Used in industrial textiles, protective clothing, and smart textiles. |

| Benefits | Increases durability, improves thermal conductivity, and offers electromagnetic shielding. |

| Environmental Impact | Recyclable at end of life, reducing the environmental footprint of textiles. |

| Market Trends | Growing demand in sectors focusing on sustainability and advanced materials. |

| Challenges | Higher cost compared to conventional fibers and the need for specialized production techniques. |

Versatile Applications: Using Metal Fiber Yarn in Different Textile Products

Metal fiber yarns have emerged as a game-changing material in the textile industry, with versatile applications across various products. Their integration into textile composites, particularly with metal-organic frameworks (MOFs), is paving the way for advanced functionality in smart textiles. A recent review highlighted that the combination of MOFs with textiles enhances properties like moisture resistance and improves overall durability, making them suitable for more demanding applications.

The application of electrospinning technology has further expanded the potential of metal fiber yarns in textile products. By synthesizing various nanofibers, including those made from metal oxides and carbon, manufacturers can create innovative fabric solutions with enhanced electrical and thermal properties. According to industry reports, the use of functional fibers in wearable heating textiles has shown superior performance, enabling the development of products that are not only responsive but also energy-efficient. These advancements open up new avenues for wearable technology, safety garments, and multifunctional fabrics.

At Shijiazhuang Shielday Technology Co., Ltd., we are committed to advancing the capabilities of textile products through our high-performance EMI shielding textiles and conductive wires. By leveraging the unique properties of metal fiber yarns, we are at the forefront of developing smart textiles that meet the diverse needs of modern consumers while ensuring sustainability and performance excellence.

FAQS

: Metal fiber yarn is a revolutionary material that enhances the performance of textile products by improving conductivity and durability, making them suitable for harsh environments.

Manufacturers should evaluate the specific performance requirements of their end products, consider custom product development services, and experiment with different blends of metal fiber yarns to achieve the desired balance between flexibility and strength.

Metal fiber yarn enhances the durability of textiles, offering superior strength and wear resistance, which helps products maintain their functionality and aesthetic appeal over time.

Metal fiber yarn can withstand high temperatures and corrosive environments, making it ideal for multifunctional applications, especially in growing fields like wearable electronics.

Metal fiber yarn, made from recycled metals, provides an eco-friendly alternative by reducing environmental impact while offering durability and conductivity without relying on traditional resources.

Metal fiber yarn allows for recycling at the end of a product's lifecycle, promoting sustainability by reducing waste and emphasizing the importance of eco-friendly practices in textile production.

Metal fiber yarn can enhance the functionality of various applications, ranging from fashion to technical textiles, making garments more versatile and long-lasting.

The increasing importance of material performance and surface treatments is promoting the use of metal fiber yarns to meet the demands for advanced technology integration in textiles.

Conclusion

Metal Fiber Yarn represents a significant advancement in textile manufacturing, offering a multitude of benefits that enhance overall product performance. One of its primary advantages is durability; the strength of metal fibers greatly increases the lifespan of textiles, making them suitable for demanding applications. Moreover, Metal Fiber Yarn improves conductivity, thereby enabling the development of smart textiles that can interact with electronic devices. It also plays a crucial role in temperature regulation, offering effective thermal management solutions for various environments.

At Shijiazhuang Shielday Technology Co., Ltd., we leverage Metal Fiber Yarn to create innovative textiles that are not only high-performing but also eco-friendly. Our commitment to sustainability is reflected in the materials we use, aligning with the growing demand for green solutions in the textile industry. Additionally, the versatility of Metal Fiber Yarn allows for a wide range of applications, from EMI shielding textiles to conductive wires, making it an essential component of our comprehensive portfolio of products and custom development services.

Related Posts

-

Understanding the Challenges with Sourcing Quality Copper Tinsel Wire

-

Exceptional Tinned Tinsel Wire Manufacturing in China for Global Buyers

-

Unmatched Manufacturing Excellence: Discover the Best High Temp Resistant Sleeves from China's Leading Factory

-

10 Industry Standards for Best Fire Resistant Fabric and 7 Reasons to Choose Them

-

Ultimate Checklist for Sourcing the Best Silver Conductive Fabric Worldwide

-

Essential Insights: Your Comprehensive Guide to Metal Gimped Wire Applications and Benefits