Unlocking the Advantages of Steel Microwire in Modern Applications

Table of Contents

- The Versatility of Steel Microwire in Various Industries

- Comparing Steel Microwire to Traditional Wire Solutions

- Innovative Uses of Steel Microwire in Technology and Engineering

- Cost-Effectiveness of Steel Microwire Over Alternative Materials

- Environmental Impacts of Steel Microwire Production and Use

- FAQS

- Conclusion

- Related Posts

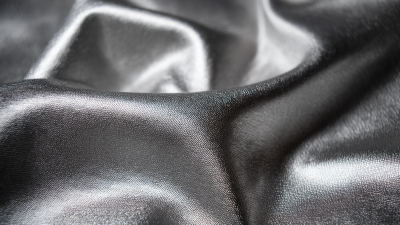

In today's fast-paced technological landscape, the demand for innovative materials is ever-increasing, and Steel Microwire stands at the forefront of this evolution. This ultimate guide delves into the myriad advantages of Steel Microwire, a product that is revolutionizing modern applications across various industries. As a leading manufacturer, Shijiazhuang Shielday Technology Co., Ltd. specializes in high-performance EMI shielding textiles and conductive wires, showcasing a full portfolio that includes specialty EMI shielding and smart textiles. Emphasizing our commitment to quality and customization, this blog will explore how Steel Microwire enhances product performance, reliability, and efficiency, making it an indispensable component in today's advanced technological solutions. Whether you are in telecommunications, automotive, or electronics, understanding the benefits of Steel Microwire can empower your innovation journey.

The Versatility of Steel Microwire in Various Industries

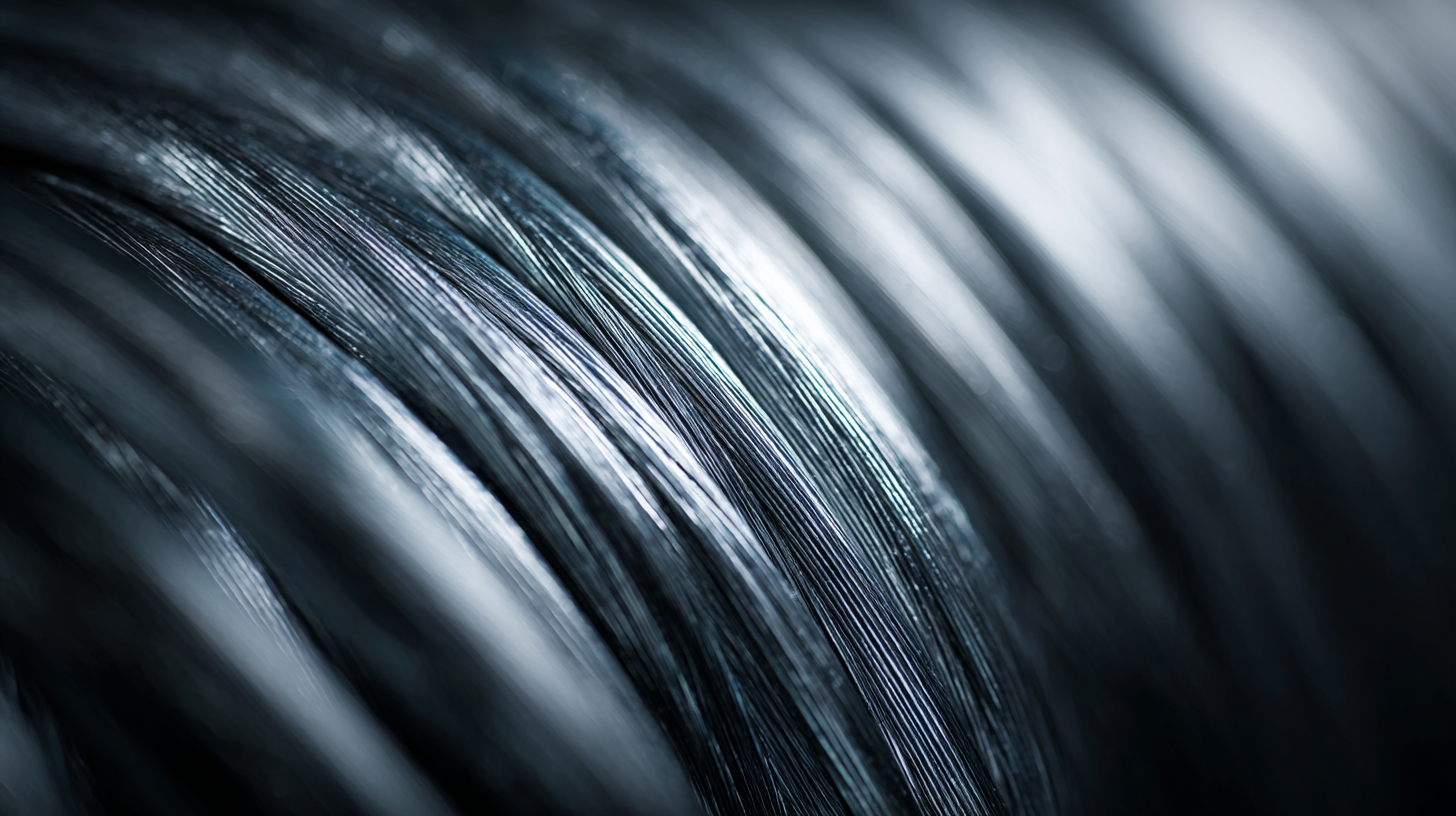

Steel microwire has emerged as a critical component across various industries due to its unparalleled versatility. Primarily utilized in electronics, steel microwire provides excellent conductivity and durability, making it ideal for manufacturing wires used in high-performance devices. Its fine diameter enhances flexibility, allowing for intricate designs while maintaining strength. This unique characteristic contributes to the development of lightweight and compact electronic products, which are essential in today's fast-paced technological landscape.

Beyond electronics, steel microwire finds applications in the medical field, particularly in the manufacturing of surgical instruments and scaffolding for tissue engineering. Its corrosion resistance and biocompatibility make it suitable for use in implants and devices that interact with biological systems. Additionally, the versatility of steel microwire extends to the automotive and aerospace industries, where it is used for reinforcement in materials and components that require high tensile strength. As industries continue to evolve, the adaptability of steel microwire will undoubtedly play a pivotal role in driving innovation and improving functionality across a wide array of applications.

Unlocking the Advantages of Steel Microwire in Modern Applications - The Versatility of Steel Microwire in Various Industries

| Industry | Application | Benefits of Steel Microwire |

|---|---|---|

| Manufacturing | Precision components in machinery | High tensile strength and durability |

| Electronics | Wiring in circuit boards | Excellent conductivity and flexibility |

| Medical | Surgical instruments and implants | Corrosion resistance and biocompatibility |

| Aerospace | Components in aircrafts | Lightweight yet strong, heat resistance |

| Construction | Reinforcement in concrete structures | Enhanced structural integrity |

Comparing Steel Microwire to Traditional Wire Solutions

In recent years, steel microwire has emerged as a revolutionary alternative to traditional wire solutions, offering unique advantages that are increasingly recognized across various industries. Unlike conventional wires, which often fall short in terms of durability and performance, steel microwire boasts enhanced mechanical properties, ensuring superior tensile strength and flexibility. This is particularly vital in applications requiring reliable and long-lasting performance, such as in emi shielding textiles where shielding effectiveness can be significantly improved. According to a recent industry report, the global demand for advanced conductive materials, including steel microwire, is projected to reach USD 1.5 billion by 2025, primarily driven by the surge in electronics and telecommunications applications.

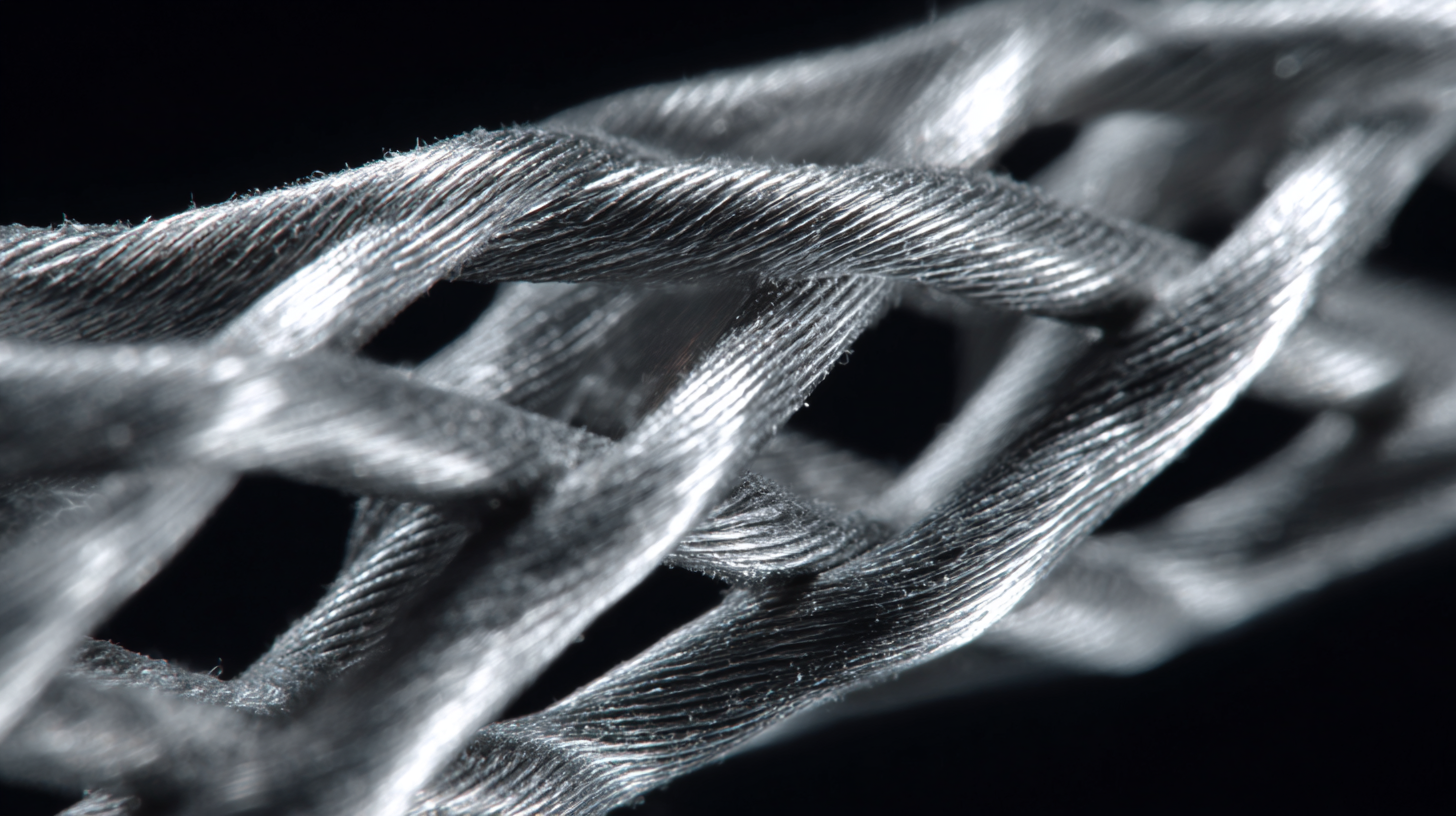

When compared to traditional wire solutions, steel microwire stands out due to its lightweight and compact design, which facilitates easier integration into various textiles and electronic devices. The smaller diameter of microwires allows for higher packing density without compromising conductivity, leading to more efficient and effective products. Furthermore, steel microwire demonstrates exceptional resistance to corrosion and oxidation, making it a preferred choice in harsh environments. Shijiazhuang Shielday Technology Co., Ltd., as an advanced manufacturer of high-performance emi shielding textiles and conductive wires, recognizes these advantages and offers a comprehensive portfolio of specialty materials designed to meet the growing demands of modern applications. Our commitment to innovation ensures that we provide cutting-edge solutions that enhance both performance and durability for our clients.

Innovative Uses of Steel Microwire in Technology and Engineering

Steel microwire is making significant strides in technology and engineering, thanks to its unique properties and innovative applications. As industries seek lightweight yet durable materials, steel microwire stands out for its strength and versatility. This material is particularly valuable in the development of neural electrodes, where both electrical conductivity and mechanical robustness are crucial. Recent advancements highlight the importance of using high-performance materials to create interfaces that facilitate communication between biological systems and machines.

In addition to biomedical applications, steel microwire is revolutionizing the field of 3D printing. Engineers are now capable of utilizing micro welding and additive manufacturing techniques to fabricate small metal parts with incredible precision. This approach allows for the production of intricate components that meet the demands of advanced electronics and engineering applications. By leveraging the extraordinary capabilities of steel microwire, researchers are opening doors to innovative manufacturing solutions that enhance the efficiency and functionality of modern devices.

Cost-Effectiveness of Steel Microwire Over Alternative Materials

Steel microwire is rapidly carving out its place in various modern applications, particularly due to its cost-effectiveness compared to alternative materials. With advancements in technology, industries are realizing that steel microwire not only offers a practical solution but also enhances performance across numerous fields.

For instance, the use of strategic dual-stratum microwire composites has shown remarkable effectiveness in electromagnetic shielding with low microwave reflectivity. These properties make steel microwire an attractive option for sectors needing robust and economical materials.

Steel microwire is rapidly carving out its place in various modern applications, particularly due to its cost-effectiveness compared to alternative materials. With advancements in technology, industries are realizing that steel microwire not only offers a practical solution but also enhances performance across numerous fields.

For instance, the use of strategic dual-stratum microwire composites has shown remarkable effectiveness in electromagnetic shielding with low microwave reflectivity. These properties make steel microwire an attractive option for sectors needing robust and economical materials.

Moreover, as seen in recent innovations, the development of uniaxially aligned microwire networks for flexible transparent electrodes exemplifies the versatility of steel microwire in electronics. Unlike other materials, the affordability of steel microwire enables wider accessibility and implementation of advanced technologies in both military and civilian applications. The integration of microwires into chaff countermeasures illustrates their importance in enhancing operational capabilities, showcasing that the cost benefits extend beyond mere manufacturing, allowing for superior performance against emerging threats. Thus, the cost-effectiveness of steel microwire solidifies its role as a critical component in modern technological advancements.

Environmental Impacts of Steel Microwire Production and Use

Steel microwire offers significant advantages in various modern applications, particularly due to its unique properties, including high tensile strength, durability, and flexibility. However, it's essential to address the environmental impacts associated with its production and use. Reports indicate that the manufacturing of steel microwire can generate considerable CO2 emissions, with estimates suggesting an average of 1.8 tons of CO2 emitted per ton of steel produced. Furthermore, the mining and processing of raw materials are also critical areas where environmental concerns arise, impacting local ecosystems and water quality.

At Shielday Technology Co., Ltd., we are committed to minimizing these impacts through sustainable manufacturing practices. Our advanced manufacturing techniques not only enhance the performance of our EMI shielding textiles and conductive wires but also emphasize eco-friendly processes. According to industry statistics, utilizing high-performance materials like steel microwire in smart textiles can reduce waste and increase product longevity. This shift towards sustainable solutions provides both environmental benefits and improved functionality for our customers, ensuring that we maintain a competitive edge in the evolving technological landscape while prioritizing the planet's health.

Unlocking the Advantages of Steel Microwire: Environmental Impacts of Production and Use

FAQS

: Steel microwire is primarily utilized in electronics for its excellent conductivity and durability, making it ideal for high-performance devices. Its fine diameter enhances flexibility for intricate designs while maintaining strength.

The unique characteristics of steel microwire allow for the development of lightweight and compact electronic products, which are essential in today’s fast-paced technological landscape.

In the medical field, steel microwire is used for manufacturing surgical instruments and scaffolding for tissue engineering due to its corrosion resistance and biocompatibility.

Steel microwire's corrosion resistance and biocompatibility make it suitable for use in implants and devices that interact with biological systems.

In the automotive and aerospace industries, steel microwire is utilized for reinforcement in materials and components requiring high tensile strength.

Steel microwire is used in the development of neural electrodes, where its electrical conductivity and mechanical robustness are crucial for creating interfaces between biological systems and machines.

Steel microwire is revolutionizing 3D printing by allowing engineers to use micro welding and additive manufacturing techniques to create small metal parts with high precision.

By leveraging its capabilities, researchers are utilizing steel microwire to enhance the efficiency and functionality of modern devices through innovative manufacturing solutions.

The adaptability of steel microwire is pivotal in driving innovation and improving functionality across various applications as industries continue to evolve.

Steel microwire addresses the need for lightweight yet durable materials in advanced electronics and engineering applications, enabling the production of intricate components with high performance.

Conclusion

Steel Microwire is emerging as a game-changing material across various industries due to its remarkable versatility and performance. Unlike traditional wire solutions, Steel Microwire boasts superior strength and flexibility, making it ideal for demanding applications in technology and engineering. Its innovative uses range from advanced EMI shielding textiles to smart conductive wires, catering to the rising needs for efficiency and reliability in modern manufacturing.

Additionally, the cost-effectiveness of Steel Microwire presents a significant advantage over alternative materials, providing businesses with enhanced functionality without compromising their budgets. Moreover, as industries increasingly focus on sustainability, the environmental impacts of Steel Microwire production and use highlight its potential to support greener manufacturing practices. At Shijiazhuang Shielday Technology Co., Ltd., we leverage these benefits through our high-performance Steel Microwire products, offering a comprehensive portfolio and custom solutions that meet diverse client needs.

Related Posts

-

How to Enhance Your Textile Products with Metal Fiber Yarn

-

Exploring Innovative Applications of Yarn Spuns Pbo Fiber in Modern Textiles

-

10 Industry Standards for Best Fire Resistant Fabric and 7 Reasons to Choose Them

-

Common Issues with Wet Wipes Nonwoven Fabric You Need to Know

-

How to Navigate Import and Export Certifications for Best Conductive Tape

-

5 Essential Tips for Choosing Silver Conductive Fabric for Your Project